These products are mainly used for tightening by screws and are inserted into a plastic molded part. The shape and insertion method depend on the molding material such as thermoplastic and thermoset plastic and the strength required. All of our products are manufactured in both domestic and overseas , thus ensuring high quality and a rapid response.

Please choose the insert nut used for different kind of plastic below

Please choose the installation method of insert nut below

Select from product list

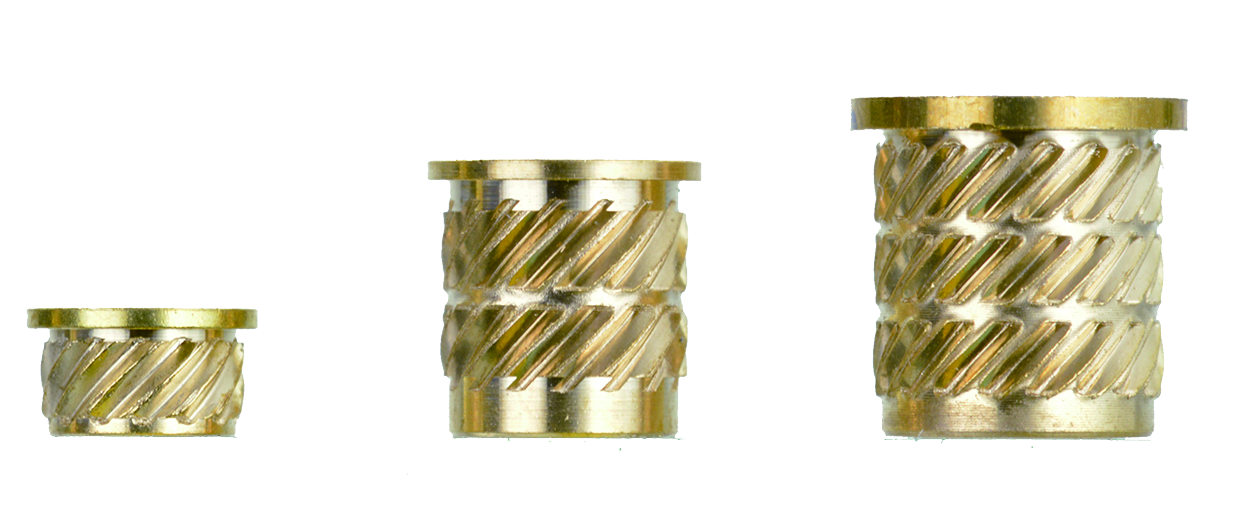

キャッチサート®(熱圧入 冷間圧入共用 後埋め用インサートナット)

外周ローレット形状が斜め同一方向になっており、インサートナットが左右対称形状で方向性がないため作業性に優れます。また当社製品の中で最も種類が多く、お客様の選択肢が大幅に増えます。

More

More

ツバ付きキャッチサート(熱圧入 冷間圧入共用 後埋め用インサートナット)

SG Lock(Heat Staking Inserts)

Knurling in alternate directions provides high tensile and torque strengths.

This most versatile insert nut has a guide on the insertion part, which supports the temporarily placed insert and ensures easy and vertical insertion.

More

This most versatile insert nut has a guide on the insertion part, which supports the temporarily placed insert and ensures easy and vertical insertion.

More

ツバ付SGロック(熱圧入 後埋め用インサートナット)

Microsert(Heat Staking Inserts)

Knurling in alternate directions provides high tensile and torque strengths.

The symmetric design without orientation increases productivity and is advantageous for automatic machinery.

More

The symmetric design without orientation increases productivity and is advantageous for automatic machinery.

More

Knife Lock (Press-In Inserts)

This insert nut has knurling in the same direction and is mainly used for thermoset plastics.

With the heat insertion, the unidirectional knurling reduces stress on plastics.

This is particularly advantageous, for example, when there is not enough clearance from the edge of the boss.

More

With the heat insertion, the unidirectional knurling reduces stress on plastics.

This is particularly advantageous, for example, when there is not enough clearance from the edge of the boss.

More

ツバ付ナイフロック (冷間圧入 後埋め用インサートナット)

Web lock(Heat Staking Inserts)

It has a knurled shape to prevent imposing stress on plastics and is mainly used for polycarbonate materials. And, as the insert nut has left-right symmetry you do not need to worry about its direction. This will greatly increase productivity, even when using automatic machines.

More

More

Tapsert(Press-In Inserts)

This insert nut is slighly striked by handle pressing machine and hammer, which make it more suitable for quick mounting. Beside that,this part also have a high efficiency of strength, by using bolt-screwing technology .

More

More

Quality Lock (Mold-in Inserts)

This is a revolutionary type of insert nut with a square groove in the middle.

Compared with conventional inserts with diamond-shaped knurling, the strength is significantly increased.

No cutting dust is generated, thus improving the quality.

More

Compared with conventional inserts with diamond-shaped knurling, the strength is significantly increased.

No cutting dust is generated, thus improving the quality.

More

Made-to-order product

Beside the listed product, our company also provide the produced on order service in order to meet the demand of customers. Please contact us if your company need a contribution for technology design and examination; prevent or solve your problem in work.

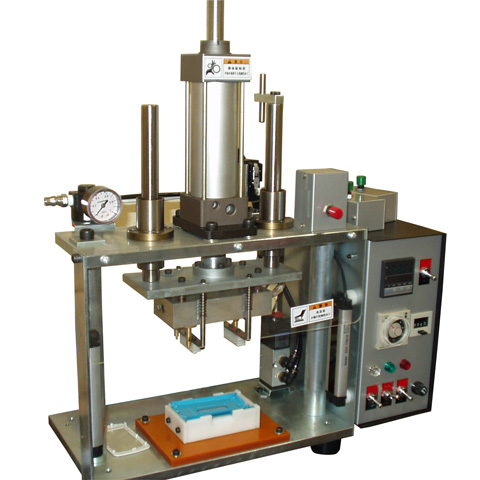

Insert-nut heat inserter

We could provide service of designing and manufacturing a variety kinds of insertion machine, such as air cylinder type, manual type or robot cylinder type. In order to meet customers's working requirement, make-to-order service available. Please consider and let us know what you want.

More

More

Insert nut's test strength service

[Overview]

Upon receiving insert nut sample from customers, we will use plastic (pellet) to run tests on the insert nut sample by using the injection molding process of our company. According to the test results, we could determine shape and strenght of product using for mass production.

More

Upon receiving insert nut sample from customers, we will use plastic (pellet) to run tests on the insert nut sample by using the injection molding process of our company. According to the test results, we could determine shape and strenght of product using for mass production.

More