Knurling in alternate directions provides high tensile and torque strengths.

The symmetric design without orientation increases productivity and is advantageous for automatic machinery.

The symmetric design without orientation increases productivity and is advantageous for automatic machinery.

- Major Insertion Methods

- Heat Staking Insertion, Ultrasonic Insertion, High Frequency Insertion

- Material

- Brass (C3604), Aluminum Alloy (made-to-order), Stainless steel (made-to-order)

- Plastic

- Thermoplastics

■ Features

・ Non-orientation design for higher productivity

・ Knurling in alternate directions provides high strength

・ Suitable for use in automatic feeders and parts feeders

・ Full compliance with RoHS Directive

・ Knurling in alternate directions provides high strength

・ Suitable for use in automatic feeders and parts feeders

・ Full compliance with RoHS Directive

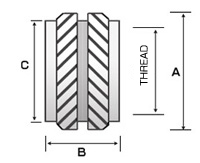

■ Dimensions

- Microsert Dimensional Drawing

- Dimensional Drawing

|

品 番

|

ね じ

|

A

|

B

|

C

|

ローレット段数

|

樹脂下穴径(参考値)

|

|

|

CS3.3ーM2-2.0

|

M2×0.4

|

3.30

|

2.00

|

3.00

|

1

|

φ3.05

|

※

|

|

Part Number

|

Thread and Pitch

|

A

|

B

|

C

|

Pilot Hole Dimension on Plastic (Reference)

|

|

|

MS2.5-M1.6-3.0

|

M1.6×0.35

|

2.5

|

3.0

|

2.10

|

φ2.2

|

※

|

|

MS2.9-M2-2.0

|

M2×0.4

|

2.9

|

2.0

|

2.40

|

φ2.6

|

※

|

|

MS3.5-M2-3.9

|

M2×0.4

|

3.5

|

3.9

|

3.10

|

φ3.2

|

|

|

MS4.4-M2.5-5.7

|

M2.5×0.45

|

4.4

|

5.7

|

3.80

|

φ4.0

|

※

|

|

MS4.6-M3-5.7

|

M3×0.5

|

4.6

|

5.7

|

3.90

|

φ4.0

|

※

|

|

MS6.3-M4-8.1

|

M4×0.7

|

6.3

|

8.1

|

5.54

|

φ5.6

|

※

|

※Standard parts Unit.mm

■ Microsert Performance Data (Reference)

|

Part Number

|

ABS

|

MC Nylon

|

PP

|

|||

|

Pull-out(N)

|

Torque-out(N-m)

|

Pull-out(N)

|

Torque-out(N-m)

|

Pull-out(N)

|

Torque-out(N-m)

|

|

|

MS2.5-M1.6-3.0

|

368

|

0.56

|

354

|

0.58

|

181

|

0.55

|

|

MS2.9-M2-2.0

|

261

|

0.41

|

289

|

0.48

|

151

|

0.27

|

|

MS4.4-M2.5-5.7

|

1,133

|

2.48

|

1,134

|

1.86

|

625

|

1.36

|

|

MS4.6-M3-5.7

|

1,666

|

2.92

|

1,424

|

2.47

|

995

|

2.31

|

|

MS6.3-M4-8.1

|

2,399

|

5.10

|

3,045

|

6.00

|

1,601

|

4.24

|

|

品 番

|

POM

|

アクリル

|

塩ビ

|

|||

|

Pull-out (N)

|

Torque-out(N-m)

|

Pull-out (N)

|

Torque-out(N-m)

|

Pull-out (N)

|

Torque-out(N-m)

|

|

|

MS2.5-M1.6-3.0

|

344

|

0.58

|

427

|

0.57

|

359

|

0.58

|

|

MS2.9-M2-2.0

|

248

|

0.51

|

418

|

0.76

|

257

|

0.71

|

|

MS4.4-M2.5-5.7

|

1,255

|

2.43

|

1,563

|

2.98

|

1,598

|

2.98

|

|

MS4.6-M3-5.7

|

1,769

|

2.96

|

3,155

|

3.92

|

1,876

|

3.09

|

|

MS6.3-M4-8.1

|

3,147

|

5.42

|

5,519

|

6.67

|

3,282

|

6.50

|

※The data above are experimental results obtained by Micro Fasteners. They are not a guarantee of the strength of our products.

1N≒0.098kgf

1N-m≒9.8kgf-cm

1N≒0.098kgf

1N-m≒9.8kgf-cm

■ NOTE

・The MS2.5-M1.6-3.0 has a different shape than the illustration above.

・ Headed inserts are also available.

・ Please contact us if you need Pb-free material for environmental reasons.

・ Pilot hole diameters are for reference only.

The diameter should be determined by tests before use.

・ Please contact us about the knurling design when knife locks are used for

polycarbonate (PC) and other materials which are sensitive to residual stress.

・ The diameter of the pilot hole for the mounting object should be smaller

than the outer diameter of the insert (Dimension C).

・ When inserts are tightened by screws, choose the screw length

so that screws do not reach the bottom of insert pilot holes.

・ The specifications are subject to change without notice.

・ Please contact us if you have any other questions.

・The MS2.5-M1.6-3.0 has a different shape than the illustration above.

・ Headed inserts are also available.

・ Please contact us if you need Pb-free material for environmental reasons.

・ Pilot hole diameters are for reference only.

The diameter should be determined by tests before use.

・ Please contact us about the knurling design when knife locks are used for

polycarbonate (PC) and other materials which are sensitive to residual stress.

・ The diameter of the pilot hole for the mounting object should be smaller

than the outer diameter of the insert (Dimension C).

・ When inserts are tightened by screws, choose the screw length

so that screws do not reach the bottom of insert pilot holes.

・ The specifications are subject to change without notice.

・ Please contact us if you have any other questions.