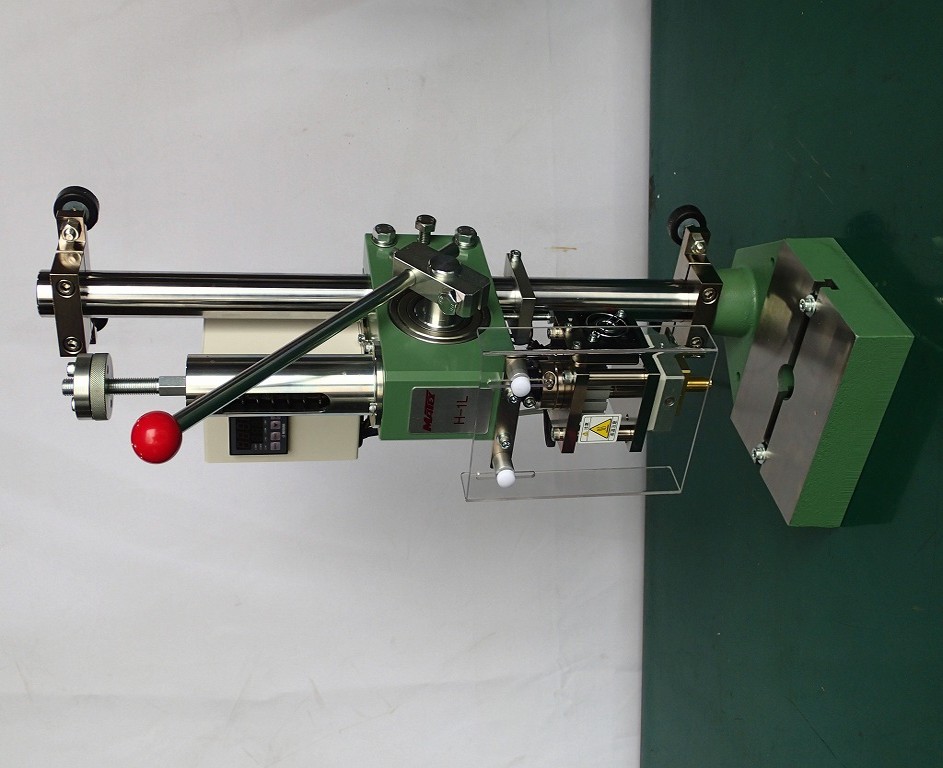

【Handheld Type】Manual Heat Inserter for Insert Nuts

Model:[HIMT-80]

■Features

・Compared to the basic model, the heat source unit has higher rigidity, enabling more stable heat insertion.

・By replacing the heater block, multiple insert nuts can be heat-inserted simultaneously.

■Features

・Compared to the basic model, the heat source unit has higher rigidity, enabling more stable heat insertion.

・By replacing the heater block, multiple insert nuts can be heat-inserted simultaneously.

■ Specifications

- Dimensions

- Approx. 200mm×370mm×550mm

- Weight

- Approx. 21kg

- Power Supply

- AC100V(50/60Hz)

■ Additional Information

Compared to the basic model, this machine allows for greater customization to suit your specific requirements.

Equipped with a standard temperature controller, allowing users to easily monitor the current insertion temperature at a glance.

Equipped with a standard temperature controller, allowing users to easily monitor the current insertion temperature at a glance.

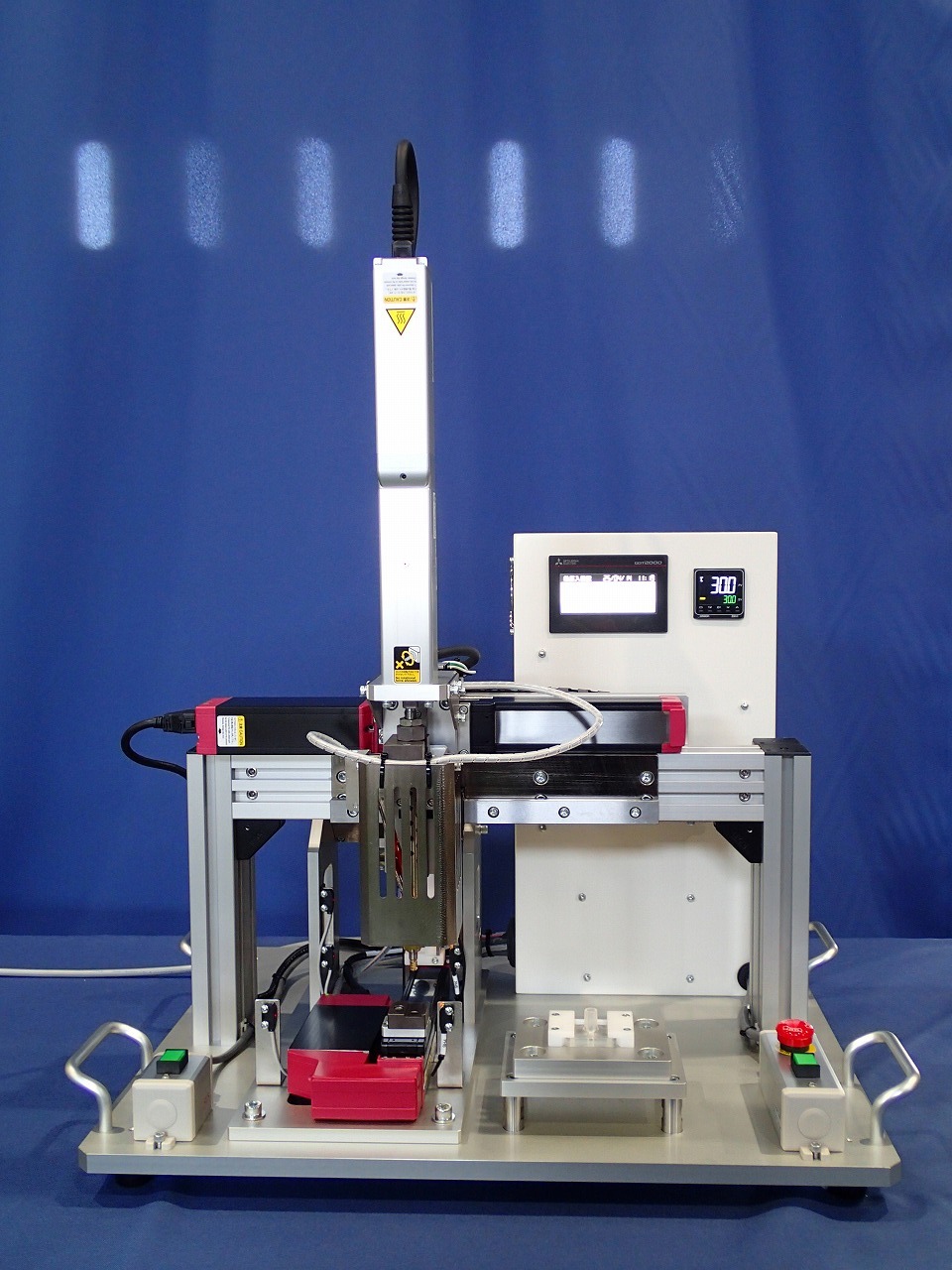

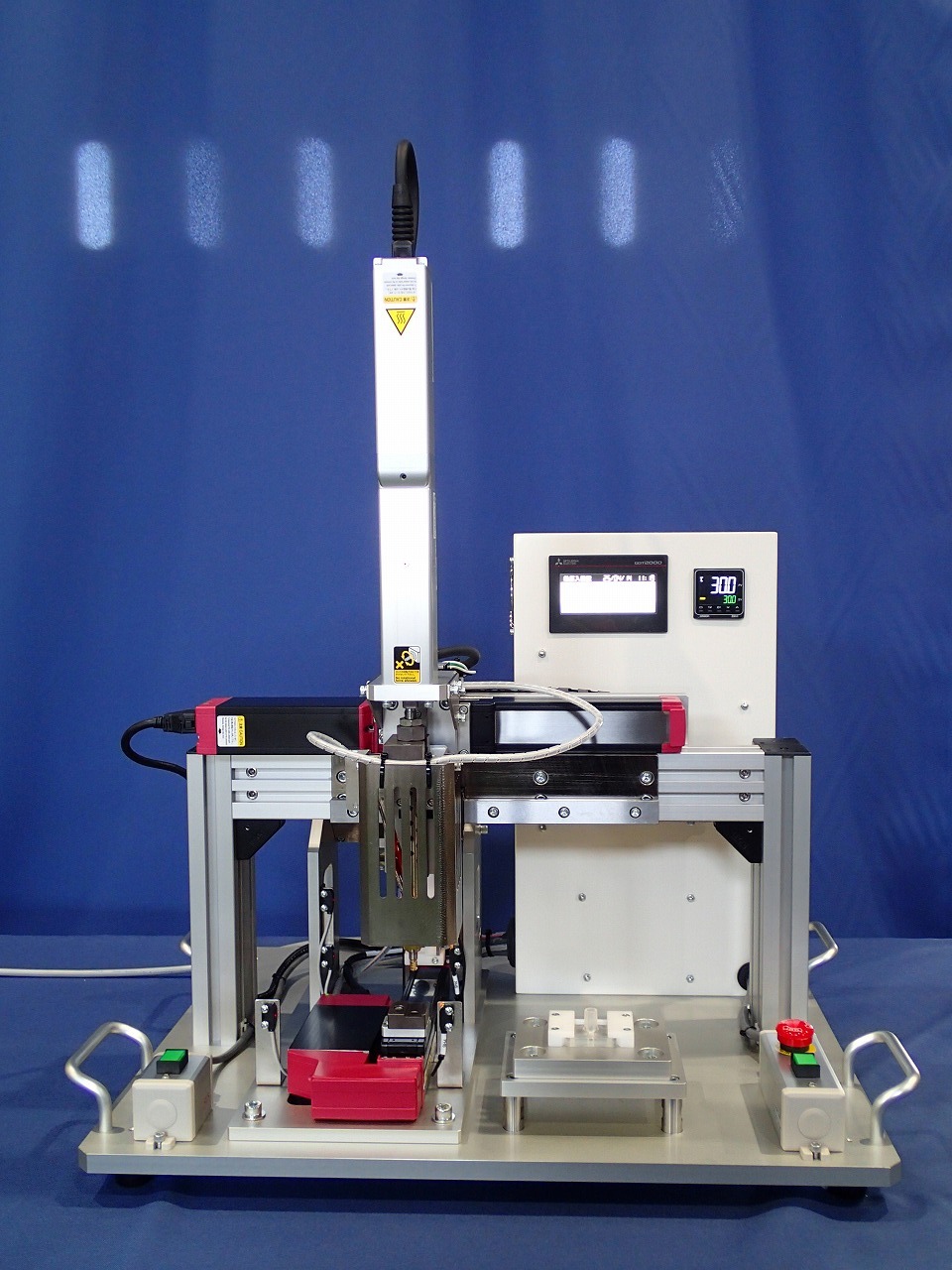

Semi-Automatic Heat Inserter for Insert Nuts

Robo-Cylinder Type – Multi-Axis Model

Model:[RIMT-4000]

■Features

・The multi-axis robo-cylinder system enables simultaneous heat insertion at multiple locations

・Enhances overall efficiency by reducing costs and shortening processing time

■Features

・The multi-axis robo-cylinder system enables simultaneous heat insertion at multiple locations

・Enhances overall efficiency by reducing costs and shortening processing time

■ Specifications

- Dimensions

- Approx. 300mm×300mm×1100mm

- Weight

- Approx. 130kg

- Power Supply

- AC(50/60Hz)

■ Additional Information

Custom-designed to match your product specifications.

The control monitor allows easy manual operation and adjustment of various timers.

The control monitor allows easy manual operation and adjustment of various timers.

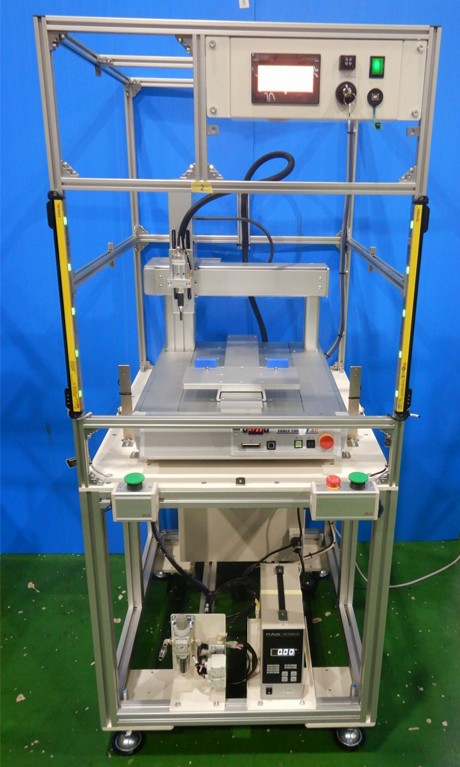

Heat Insertion Machine with Automatic Feeding System

Model:[RIMT-6000]

■Features

・Automatic nut feeding from the nut feeder, with an alert function when the supply runs low

・Easy operation via touch panel, allowing count display and various settings

・Fine-tuning of parameters enables significant improvements in automation and efficiency

・All settings can be clearly adjusted on the display, making the machine user-friendly regardless of operator experience

■Features

・Automatic nut feeding from the nut feeder, with an alert function when the supply runs low

・Easy operation via touch panel, allowing count display and various settings

・Fine-tuning of parameters enables significant improvements in automation and efficiency

・All settings can be clearly adjusted on the display, making the machine user-friendly regardless of operator experience

形式:[RIMT-6000 型]

■特徴

・ナットフィーダーからの自動供給、ナットが少量になった際にもアラート機能あり

・「タッチパネル」を使用してカウント表示から各種設定を簡単に行うことが出来ます

・各パラメーターを細かく設定することにより、自動化と効率を大幅に向上します

・細かな設定もディスプレイで行え設定が明確に出来るため、作業者を選びません

■特徴

・ナットフィーダーからの自動供給、ナットが少量になった際にもアラート機能あり

・「タッチパネル」を使用してカウント表示から各種設定を簡単に行うことが出来ます

・各パラメーターを細かく設定することにより、自動化と効率を大幅に向上します

・細かな設定もディスプレイで行え設定が明確に出来るため、作業者を選びません

形式:[RIMT-6000 型]

■特徴

・ナットフィーダーからの自動供給、ナットが少量になった際にもアラート機能あり

・「タッチパネル」を使用してカウント表示から各種設定を簡単に行うことが出来ます

・各パラメーターを細かく設定することにより、自動化と効率を大幅に向上します

・細かな設定もディスプレイで行え設定が明確に出来るため、作業者を選びません

■特徴

・ナットフィーダーからの自動供給、ナットが少量になった際にもアラート機能あり

・「タッチパネル」を使用してカウント表示から各種設定を簡単に行うことが出来ます

・各パラメーターを細かく設定することにより、自動化と効率を大幅に向上します

・細かな設定もディスプレイで行え設定が明確に出来るため、作業者を選びません

形式:[RIMT-6000 型]

■特徴

・ナットフィーダーからの自動供給、ナットが少量になった際にもアラート機能あり

・「タッチパネル」を使用してカウント表示から各種設定を簡単に行うことが出来ます

・各パラメーターを細かく設定することにより、自動化と効率を大幅に向上します

・細かな設定もディスプレイで行え設定が明確に出来るため、作業者を選びません

■特徴

・ナットフィーダーからの自動供給、ナットが少量になった際にもアラート機能あり

・「タッチパネル」を使用してカウント表示から各種設定を簡単に行うことが出来ます

・各パラメーターを細かく設定することにより、自動化と効率を大幅に向上します

・細かな設定もディスプレイで行え設定が明確に出来るため、作業者を選びません

■ Specifications

- Dimensions

- Approx. 600mm×480mm×670mm

- Weight

- Approx. 20kg

- Power Supply

- AC100V(3.5A)

■ Additional Information

We can customize the machine to accommodate different nut sizes and types of nut feeders as needed.

|

品 番

|

ね じ

|

A

|

B

|

C

|

ローレット段数

|

樹脂下穴径(参考値)

|

|

|

CS3.3ーM2-2.0

|

M2×0.4

|

3.30

|

2.00

|

3.00

|

1

|

φ3.05

|

※

|

We offer customized heat inserter machine solutions for insert nuts based on your specific requireme

For example:

|

Customers with limited budgets or low production volumes

|

We recommend the Handheld Type

|

|

Customers with larger budgets and higher production needs, requiring multiple insert nuts per cycle

|

We recommend the Robo-Cylinder Type

|

With the Robo-Cylinder Type Press-Fit Machine, you can precisely control press-fit speed, torque, and insertion depth (bottom dead center position), ensuring high-precision operations.

Advantages of Heat Inserter

1.Improved Work Efficiency

Enables simultaneous insertion at 2–3 points after molding

2.Temperature Control

Precise temperature regulation ensures high insertion accuracy

3.Programmable Insertion Settings

Prevents human error and defects by automating insertion conditions

4.Ease of Operation

Simple actions such as pressing a button or pulling a handle make operation effortless

5.Prevention of Molding Issues

Minimizes waste of molded parts and insert nuts

6.High Scalability

Flexible customization available based on a modular design framework

Enables simultaneous insertion at 2–3 points after molding

2.Temperature Control

Precise temperature regulation ensures high insertion accuracy

3.Programmable Insertion Settings

Prevents human error and defects by automating insertion conditions

4.Ease of Operation

Simple actions such as pressing a button or pulling a handle make operation effortless

5.Prevention of Molding Issues

Minimizes waste of molded parts and insert nuts

6.High Scalability

Flexible customization available based on a modular design framework

Order Process

Trust us with your heat staking equipment solutions.

In addition to press-fit machines, we design and manufacture everything from simple jigs and fixtures to large-scale production equipment—customized to your requirements, including both hardware and software.

In addition to press-fit machines, we design and manufacture everything from simple jigs and fixtures to large-scale production equipment—customized to your requirements, including both hardware and software.

We also provide the most suitable insert nuts for your heat staking system, based on:

・Your manufacturing process

・Technical expertise

・Application-specific component knowledge

With our extensive know-how, we deliver fast and optimal solutions tailored to your needs!

・Your manufacturing process

・Technical expertise

・Application-specific component knowledge

With our extensive know-how, we deliver fast and optimal solutions tailored to your needs!

Other Products We Offer

Impulse Heat Staking Machine

Impulse Heat Staking Machine

・Utilizes impulse heating to instantly heat the tip of the heater for insert nut insertion.・Heats only during insertion, preventing heat-related damage to the equipment

・Ready for use immediately after power is turned on

High-Frequency Heat Staking Equipment

High-Frequency Heat Staking Equipment

・Instantly heats only the insert nut before pressing it into the plastic part・Ready for use immediately after power-up

・One high-frequency unit is required for every 1 to 3 insert nuts

Ultrasonic Heat Staking Equipment

Ultrasonic Heat Staking Equipment

・No preheating required—ready for use immediately after power-on・Heat is generated within the insert nut or welded material itself through vibration of the horn tip

・Since the equipment itself does not heat up, thermal damage to the machine is minimized